Fibers in Fiberglass Reinforced Polymers (FRP)

When manufacturing Fiberglass Reinforced Polymers (FRP) many different fibers or reinforcements may be used including: polyester fibers, natural fibers, carbon fibers, arimid fibers, and of course, the most common- glass fibers. The arrangement and combination of fiber reinforcements, along with resins, will in large part determine many of the characteristics of your final product. However, specialized techniques and proprietary processes can further enhance your FRP product (i.e. corrosion resistance, abrasion resistance, flame retardance, ultraviolet light protection, expansion etc).

Surfacing Mat

Surfacing mat or veil is a thin fiber mat made of monofilament and is not considered a reinforcing material. It is used to provide a good surface finish because of its effectiveness in blocking out the fiber pattern of the underlying mat or fabric. Surfacing mat can also be used to produce a smooth, resin-rich surface to help you achieve your desired specifications.

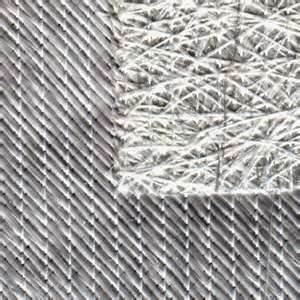

Reinforcing Mat

Made from either continuous strands laid down in a swirl pattern or from chopped strands, reinforcing mat is held together with a resinous binder or mechanically stitched. These mats are used for medium-strength composites. Combination mat, consisting of woven roving and chopped strand mat bonded together, is used to save time and resources in hand lay-up operations.

Chopped Fibers

Chopped strands or fibers are available in varying lengths for blending with resins and additives to prepare molding compounds for compression or injection molding and other processes. Various surface treatments are applied to ensure optimum compatibility with different resin systems.

Woven Fabrics

Made of fiber yarns, woven fabrics are of a finer texture than woven roving. They are available in a range of sizes and in various strength orientations.

Continuous Strand Roving (glass filament)

Continuous roving is typically chopped for spray-up, pre-form or sheet molding compounds. In the continuous form, it is used in pultrusion and filament-winding processes throughout the fiberglass industry.

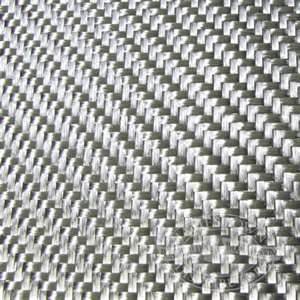

Woven Roving

This is a heavy, easy to work with, fabric available in various widths, thicknesses and weights. Woven roving can be used to provide high strength in large structural components such as tanks and vessels. Woven roving is used primarily in hand lay-up processing throughout the fiberglass industry.