FRP Filament Winding

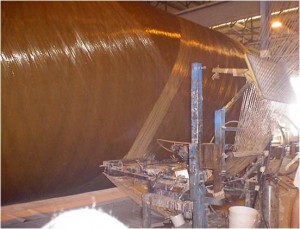

Filament winding is the process of winding resin-impregnated fiber or tape on a mandrel surface in a precise geometric pattern. This is accomplished by rotating the mandrel while a delivery head precisely positions fibers on the mandrel surface. By winding continuous strands of carbon fiber, fiberglass or other material in very precise patterns, structures can be built with properties stronger than steel at much lighter weights.

Filament winding is the process of winding resin-impregnated fiber or tape on a mandrel surface in a precise geometric pattern. This is accomplished by rotating the mandrel while a delivery head precisely positions fibers on the mandrel surface. By winding continuous strands of carbon fiber, fiberglass or other material in very precise patterns, structures can be built with properties stronger than steel at much lighter weights.

At Beetle Composites we offer custom filament wound high quality Fiberglass Reinforced Polymer (FRP) pipe and ductwork. We use multiple Computer Numeric Control (CNC) software applications to deliver precise geometric filament winding of piping and ducting. In addition, we have CNC table capabilities to perform precision processes such as router head, machine plate, and structural shape configurations.

Diameters from ½” to 14’ fiberglass piping and ducting from Beetle Plastics can meet virtually any need or application you may have. We have mandrels of varying sizes to accommodate your specific design needs.

Leading the Industry with Innovative Solutions

The custom filament wound FRP pipe, ductwork and tanks created at Beetle Composites are ideal for some of the harshest environments and can be utilized in many applications. The high quality filament-wound construction and resin/glass layering makes this an economical solution to dealing with highly corrosive environments. FRP is extremely light weight when compared with steel and other metals, and greatly reduce costs associated with installation of pipe, ductwork and tank structures.

The custom filament wound FRP pipe, ductwork and tanks created at Beetle Composites are ideal for some of the harshest environments and can be utilized in many applications. The high quality filament-wound construction and resin/glass layering makes this an economical solution to dealing with highly corrosive environments. FRP is extremely light weight when compared with steel and other metals, and greatly reduce costs associated with installation of pipe, ductwork and tank structures.

FRP Benefits

- Corrosion resistant

- Chemical resistant

- Abrasion resistant

- Economical

- Low weight to strength ratio

FRP Design Considerations

- Resin selection

- Control of dimensions and tolerances

- Desired stiffness and elasticity of FRP product

- Pressure applications