Jack Mallinson of FMC Corporation’s plant in Front Royal, Virginia, working in conjunction with Beetle Plastics, then located in Fall River, Massachusetts, conducted some of the earliest work in improving abrasion resistance of FRP pipe. These original developments took place

Jack Mallinson of FMC Corporation’s plant in Front Royal, Virginia, working in conjunction with Beetle Plastics, then located in Fall River, Massachusetts, conducted some of the earliest work in improving abrasion resistance of FRP pipe. These original developments took place

in the late 1960’s and early 1970’s.

This work found that significant increases in abrasion resistance could be achieved by adding armoring modifiers to the resin used for the internal corrosion barrier of the pipe. In those early days, the best modifiers were various forms and grades of aluminum oxides. There were problems in getting the aluminum oxide to disperse and “wet out”. However, once the aluminum oxide dispersed, improvements of abrasion life in the magnitude of two to three times over a non-modifi ed resin were achieved. The resin matrix used in those days was typically the Hetron 197 polyester resin.

While some companies that make so-called abrasion resistant pipe still use that same filler approach and formulation from the late 1960’s, Beetle continued to find a better way. In the early 1970’s, working with the late Walt Szymanski of Hooker Chemical, Beetle Plastics made major advances in the technology of abrasion resistance in FRP composites. In an extensive series of tests conducted in conjunction with Hooker, Beetle discovered that three fabrication techniques significantly influence the resulting abrasion resistance of the composite laminate.

Type of Resin: The type of resin used in making the inner abrasion/corrosion liner of the pipe influences the resulting abrasion resistance of the pipe. Special developmental elastomeric and epoxy vinyl ester resins signifi cantly increase the abrasion service life. Beetle Plastics

worked closely with Dow Chemical and Interplastics in developing these experimental resins. The selection of the proper resin, along with specifi c resin modifi cations, increases abrasion resistance by a factor of two to three times over a standard polyester or epoxy resin.

Type of Reinforcement: Beetle also discovered, in these series of Hooker tests, that the type of reinforcements used in the matrix signifi cantly infl uenced the abrasion resistance of the inner abrasion/corrosion liner. The tests demonstrated that specific types of

reinforcements greatly improved abrasion resistance of the laminate.

Also, a specific combination of selected reinforcements was critical to obtaining the optimum abrasion resistance. As the result of that knowledge, Beetle Plastics now uses a unique combination of laminate reinforcements that help significantly improve the total abrasion resistance of the composite laminate.

Armoring Modifier: Building on the early work done with FMC, Beetle conducted extensive tests to improve armoring modifiers. Beetle succeeded in developing a new type of modifier that provides superior armoring of the FRP composite. This material compares in toughness to

basalt, which in its natural form is often used as abrasion liners for steel pipe.

Over the years, Beetle Plastics has fine-tuned the specific grades of this armoring modifier material, selecting those that demonstrate the best performance in abrasion resistant FRP composite pipe. Beetle also developed techniques to gain the optimum dispersion and wetting out of this armoring modifier within the resin. Getting this ideal resin “hook” to the armoring modifier is also an important consideration when developing the best possible abrasion resistance of FRP laminates.

In order to gain maximum abrasion resistance from FRP composite pipe and laminates, it takes careful selection of all three of the important factors (resin, reinforcements, and armoring modifiers), in the proper ratios and interactions. Test results from this research indicate reductions in abrasion loss in FRP composite laminates to just one-tenth that of non-modified laminates. In other words, you might expect increased service life of ten times, or more, from Beetle Plastics abrasion resistant composite pipe and ducts.

But, to paraphrase an old saying – “the proof is in the pudding”. For FRP composite abrasion resistant pipe, the proof is in the service life obtained in actual fi eld installations.

In tests, control installations showed substantial abrasion wear and failure in just several months of service life. Regular six-month and annual inspections at these plants of Beetle Plastics abrasion resistant pipe and elbows (an elbow is an area of high abrasive wear) showed little discernable wear.

Beetle continues to refine our FRP pipe abrasion resistant technology. As a result, you can confidently turn to Beetle Plastics for the best FRP composite abrasion resistant piping system available.

Customers at numerous projects have achieved outstanding FRP piping service life in highly abrasive applications such as lime slurry, fly ash slurries, and the extremely abrasive bottom ash service.

Contact us today and we can arrange a test installation in your plant comparing Beetle Plastics abrasion resistant pipe with your current piping and duct materials.

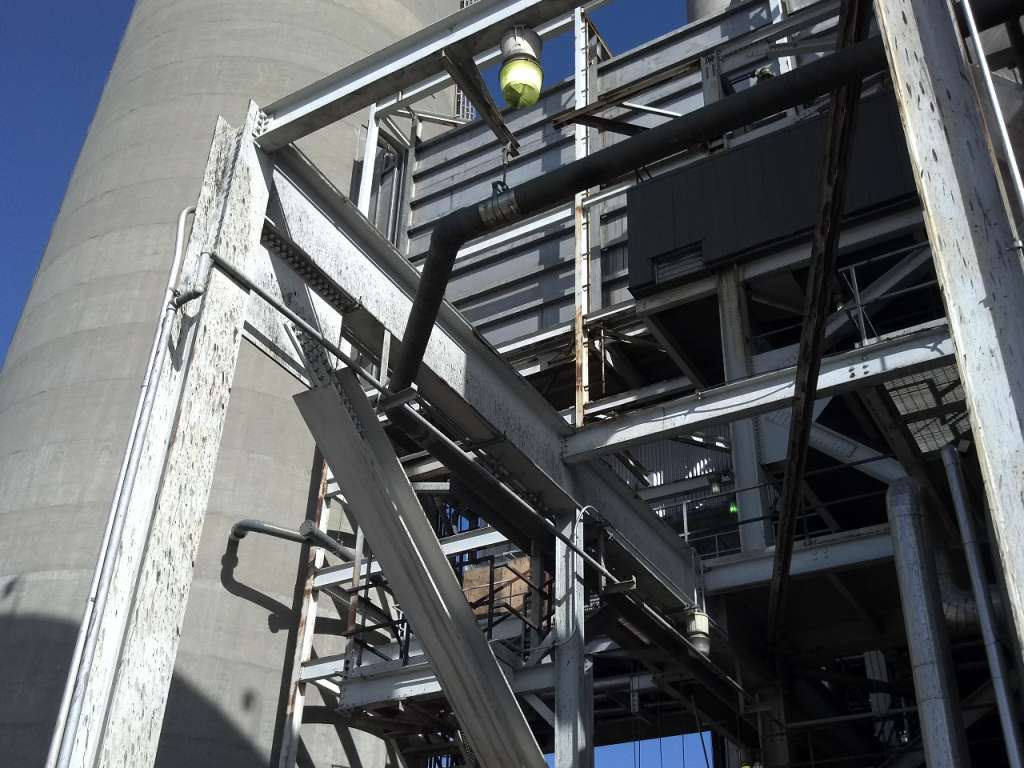

One of the many advantages of working with fiberglass is its versatility. Fiberglass can be used in abrasive and corrosive applications, but it can also be used to create custom parts to fit almost any need. Which is why we were so excited to help Westar Energy, the largest electrical power producer in Kansas, develop a fiberglass pipe solution in one of their coal-fired centers.

One of the many advantages of working with fiberglass is its versatility. Fiberglass can be used in abrasive and corrosive applications, but it can also be used to create custom parts to fit almost any need. Which is why we were so excited to help Westar Energy, the largest electrical power producer in Kansas, develop a fiberglass pipe solution in one of their coal-fired centers.

Fiber Reinforced Polymers (FPR), or fiberglass, is an excellent construction material. Used throughout the world in a wide range of industrial and non-industrial applications, FRP boasts cost-effectiveness, design flexibility, dimensional stability, high strength-to-weight ratio, durability, and low maintenance costs—among other things.

Fiber Reinforced Polymers (FPR), or fiberglass, is an excellent construction material. Used throughout the world in a wide range of industrial and non-industrial applications, FRP boasts cost-effectiveness, design flexibility, dimensional stability, high strength-to-weight ratio, durability, and low maintenance costs—among other things.  Many industries report major problems with corrosion each year. It’s a serious problem that can impact production and safety. According to the World Corrosion Organization, the estimated

Many industries report major problems with corrosion each year. It’s a serious problem that can impact production and safety. According to the World Corrosion Organization, the estimated  The corrosion and abrasion resistance of fiberglass reinforced plastics (FRP) make FRP ideal for handling caustic and abrasive manufacturing processes. The manufacturing of chlorine is one application where the benefits of FRP can make a large impact on the level of maintenance a facility will need and the overall efficiency of the process. To understand the impact FRP can have on chlorine manufacturing it is helpful to have an understanding of the process by which chlorine is produced.

The corrosion and abrasion resistance of fiberglass reinforced plastics (FRP) make FRP ideal for handling caustic and abrasive manufacturing processes. The manufacturing of chlorine is one application where the benefits of FRP can make a large impact on the level of maintenance a facility will need and the overall efficiency of the process. To understand the impact FRP can have on chlorine manufacturing it is helpful to have an understanding of the process by which chlorine is produced.

After some time in operation, it was determined that there were areas of “high wear” in one of the 8 inch

After some time in operation, it was determined that there were areas of “high wear” in one of the 8 inch  The

The

Jack Mallinson of FMC Corporation’s plant in Front Royal, Virginia, working in conjunction with Beetle Plastics, then located in Fall River, Massachusetts, conducted some of the earliest work in improving abrasion resistance of

Jack Mallinson of FMC Corporation’s plant in Front Royal, Virginia, working in conjunction with Beetle Plastics, then located in Fall River, Massachusetts, conducted some of the earliest work in improving abrasion resistance of