Lime Slurry Piping Reduces Westar Plant Downtime

One of the many advantages of working with fiberglass is its versatility. Fiberglass can be used in abrasive and corrosive applications, but it can also be used to create custom parts to fit almost any need. Which is why we were so excited to help Westar Energy, the largest electrical power producer in Kansas, develop a fiberglass pipe solution in one of their coal-fired centers.

One of the many advantages of working with fiberglass is its versatility. Fiberglass can be used in abrasive and corrosive applications, but it can also be used to create custom parts to fit almost any need. Which is why we were so excited to help Westar Energy, the largest electrical power producer in Kansas, develop a fiberglass pipe solution in one of their coal-fired centers.

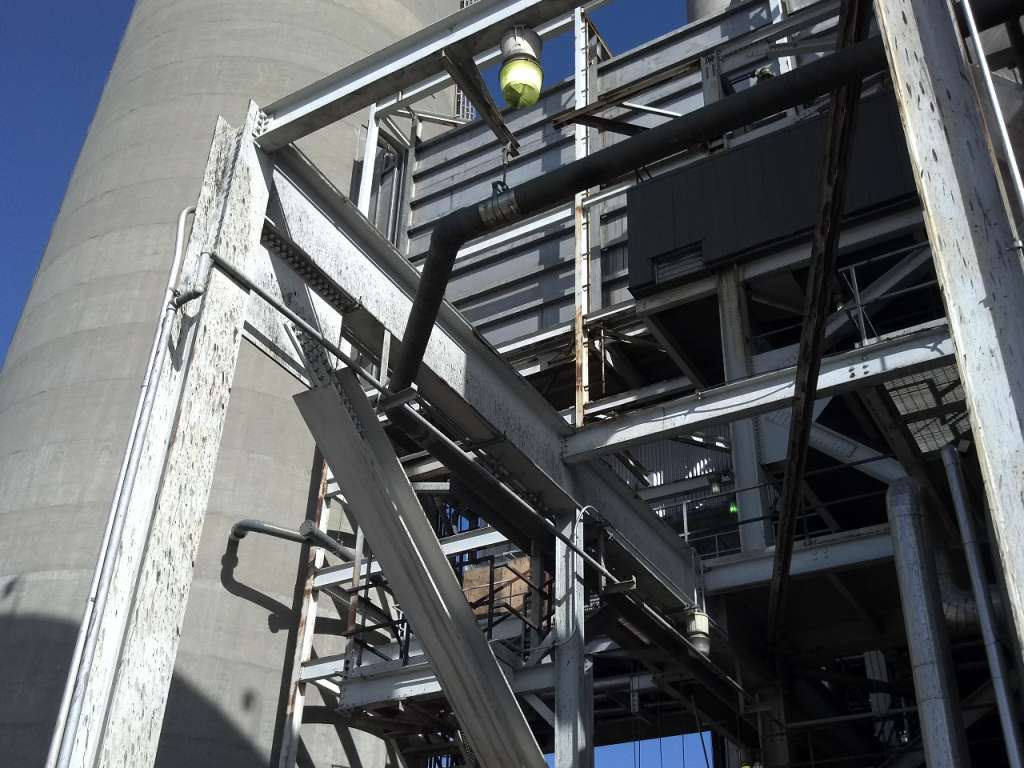

Three years ago Westar Energy refurbished a Flue Gas Desulfurization (FGD) system. Designed to remove sulfur dioxide, the system makes use of an abrasive limestone slurry. The limestone slurry caused areas of the system to experience high wear. When high wear areas needed to be replaced the system had to be shut down, resulting in costly downtime. We worked with Westar Energy to identify problem areas throughout the system and made design changes the reduced downtime and repair costs.

To find out how we helped the largest electrical power producer in Kansas design an abrasive resistant solution that helped reduce plant downtime, read the Westar FRP case study here.

After some time in operation, it was determined that there were areas of “high wear” in one of the 8 inch

After some time in operation, it was determined that there were areas of “high wear” in one of the 8 inch  The

The