FRP vs Aluminum: A Snapshot Comparison of Two Materials

FRP and Fiberglass

FRP and Fiberglass

Fiberglass is ubiquitous in a wide range of industries from pulp and paper, wastewater, desalination, and power generation to mining and mineral extraction, marine, petrochemical and chemical processing. There are significant differences with respect to mechanical properties when comparing fiberglass or fiber reinforced polymers (FRP) with metals such as steel or aluminum. Fiberglass is anisotropic, that is, they posses mechanical properties only in the direction of the applied load. In other words, their best mechanical properties are in the direction of the fiber placement. Conversely, steel and aluminum are isotropic, giving them uniform properties in all directions, independent of the applied load.

Fiberglass has exceptional inherent dimensional stability potential due to its unique formulations. Because composites are customizable, they can be designed to maximize the benefits of structural properties. Furthermore, fiberglass materials are often selected by engineers for applications requiring stringent dimensional stability under a variety of extreme conditions. Good dimensional stability or structure, and other properties such as lightweight, strength, toughness, damage tolerance, fatigue and fracture resistance, notch sensitivity, and general durability, make fiberglass desirable for many applications. Moreover, the inherent corrosion resistant characteristic of fiberglass makes it a cost-‐effective, strong, lightweight solution for corrosion resistant equipment applications in a multitude of industries including chemical processing, wastewater management, and oil and gas.

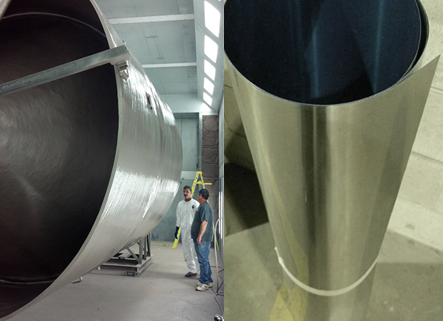

When comparing strength of materials of equivalent thicknesses and sizes, fiberglass will weigh one seventh as much as steel and half as much as aluminum. There are other very distinct advantages to having specific strength. For example, lightweight properties are important when considering the cost and ease of installation, especially for pipe and tank. FRP has another inherent edge over other products when equipment must be mounted on uneven services, existing structures, such as scrubbers, and on mezzanines or rooftops. Having lightweight properties also works well for specialty applications such as tank trailers.

Aluminum

Aluminum is an abundant element in the Earth’s crust that is widely used throughout the world in a broad range of applications, almost always as an alloy for construction purposes. Its unique combination of properties makes aluminum one of the most versatile engineering and construction materials. Aluminum is refined through the Bayer Process from aluminum ore or bauxite and once refined can be easily formed, machined and cast.

Some key properties include lightweight (about 1/3 mass, of equivalent volumes of steel, copper), excellent thermal and electrical conductivity, highly reflective to radiant energy, highly corrosion resistant to air and water (including sea water), and it’s highly workable into almost any structural shape. Corrosion resistance is a crucial property that can’t be overlooked; when aluminum is exposed to atmospheric conditions a thin oxide layer forms and protects the metal from further oxidation—this makes aluminum attractive as long-‐term viable solution for many applications. This coating or layer provides protection and allows aluminum to often be used without any type of coating or paint.

One of the most important components of aluminum’s corrosion resistance is that the aluminum oxide layer formed is impermeable, adheres well to the parent material, and if damaged the oxide layer can repair itself immediately, generally speaking the layer is stable in a pH range of 4-‐9.

So how does aluminum react in chemical environments? Generally speaking aluminum has good resistance to many organic compounds and some moderately alkaline water solutions, and most inorganic salts. As such aluminum materials are often used in the production and storage of many chemicals. One point of interest, for this article involves the pH range. A low or high pH range (below 4 or above 9) can lead to the oxide layer dissolving and corrosive attack. For example inorganic acids, strong alkaline solutions, and heavy metal salts are extremely corrosive to aluminum.

A key takeaway from this article, with respect to aluminum, is that there are important corrosion resistant limitations, and or chemical resistance limitations. For example, aluminum is susceptible to pitting corrosion, this typically happens in the presence of an electrolyte in dissolved salts, usually chlorides. Fiberglass is not susceptible to pitting corrosion in the presence of chlorides.

As with any material, limitations of one create opportunities for others. For example, aluminum is not compatible with, and should not be used in applications that included hydrochloric acid or sulfuric acid. Similarly it is not recommended for service environments that contain chlorine, sodium hypochlorite and ferric chloride, thus making it not an ideal candidate for some wastewater treatment applications.

Conversely, fiberglass has excellent corrosion properties for organic and inorganic compounds, alkaline and acidic environments including chemical resistance to the chemicals mentioned above. Fiberglass is now commonly used in wastewater treatment and or chemical processing applications using sodium hypochlorite, chlorine and or ferric chloride.

Similarly, there are structural property limits such as fatigue strength or fatigue limit that must be considered by engineers. For example, aluminum has no defined fatigue limit (fatigue failure eventually occurs) engineers must assess loads and designs for a fixed life. In contrast, when designed properly, fiberglass does not

creep, and has outstanding dimensional stability; fiberglass is strong lightweight and durable and in many cases a cost-‐effective solution.

To summarize, fiberglass has a higher-‐strength to weight ratio and better corrosion resistance in a wide range of chemical applications, when compared to aluminum. When working with fiberglass corrosion resistance can be enhanced by modifying the corrosion barrier to design specifications. Both offer design flexibility and some degree cost-‐effectiveness with respect to reduced maintenance and long life cycles. An important structural difference is that fiberglass is anisotropic, while aluminum is isotropic. Both are limited by manufacturing processes and design.